Over 30 years of PCC

Milestones in the history of PCC

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2000

- 1999

- 1998

- 1997

- 1996

- 1994

- 1993

Holding & Projects

The image shows the planned location of the project, the site of the Chemours titanium dioxide plant in DeLisle, Mississippi (USA). Copyright: Chemours.

In December, PCC SE concludes a chlorine supply contract with the US chemical company Chemours. This forms the commercial basis for the planned construction and operation of a chlor-alkali plant on the site of Chemours’ titanium dioxide plant in DeLisle, Mississippi (USA). The new plant is designed to maximize energy efficiency using state-of-the-art technology and achieve an annual nominal capacity of up to 340,000 tons. Construction is scheduled to begin in early 2026, with the plant expected to start operations in 2028. The project is a significant milestone in the expansion of PCC Group’s core business areas in global growth markets.

Logistics

PCC Intermodal S.A. will become the market leader in intermodal transport in its home market of Poland in 2024. This is according to figures from the Polish Rail Transport Office. Accordingly, the PCC Group company is the largest Polish provider of combined container transport by rail and road in 2024, with a 19.6% share of freight turnover and 17.4% of transported freight weight.

The photo shows the contract signing: Dr. Peter Wenzel (3rd l.), CEO of PCC SE, Waldemar Preussner (2rd l.), Chairman of the Supervisory Board, and Peter Berger (l.), Head of Legal, with representatives from Bay City.

We are also planning an oxyalkylates production in the USA in addition to the project in Malaysia that is currently in the construction phase. At the potential location in Bay City, Matagorda County, Texas, on the Gulf of Mexico, we reached a milestone on September 15, 2023 with the signing of a lease agreement for a plot of land near the port. The location is characterized by excellent infrastructure and a direct connection to the port of Bay City.

Logistics

PCC Intermodal SA is expanding its network with a connection between Poland and Italy. Starting in September, PCC Intermodal SA will operate a regular connection with full container trains between its intermodal terminal in Gliwice, Poland, and the northern Italian city of Padua.

The EU is funding the research project of PCC Thorion GmbH, Fraunhofer ISE and the universities of Freiburg and Duisburg-Essen to develop an anode material for more powerful lithium-ion batteries. The financing partner EIT RawMaterials, which belongs to the European Institute of Innovation and Technology, supports the project as part of the KAVA 9 funding program. EU funding amounting to 3.5 million euros is being used for the project.

(second from right: Peter Berger, member of the management team of PCC SE).

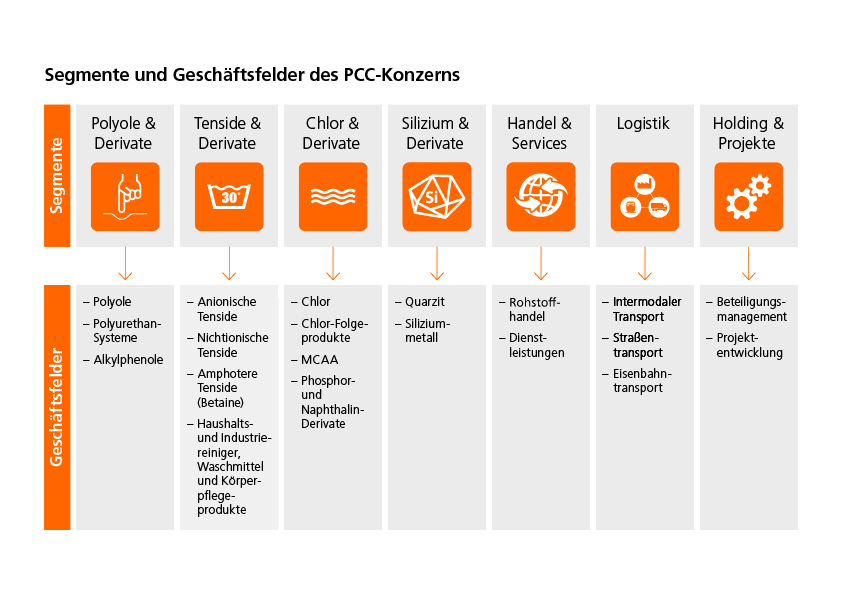

As of January 1, 2022, the PCC Group has a new segment structure considering the developments in our group of companies in recent years. In particular, the activities of the three segments of specialty chemicals, energy as well as consumer goods are rearranged and we also create separate new segments for our activities in the two areas of silicon metal and trading. Overall, the new structure comprises seven segments instead of the previous eight: Polyols & Derivatives, Surfactants & Derivatives, Chlorine & Derivatives, Silicon & Derivatives, Trading & Services, Logistics and Holding & Projects.

In August, Malaysian state-owned company Mentri Besar Terengganu (Incorporated), MBI, signs an expression of interest in August to acquire a 5% stake in joint venture company PCG PCC Oxyalkylates Sdn. Bhd. The joint venture, founded in 2020, is building a plant to produce oxyalkylates at the Kertih site in the Malaysian state of Terengganu. The plant construction commenced on October 28, 2021 and commissioning is planned for the third quarter of 2023.

Holding

By means of the introduction of a new management structure, PCC SE is embarking on long-term preparations for a generational change in the Group’s leadership. In September, the new structure consisting of an Executive Board and a Supervisory Board replaced the previous system consisting of an Administrative Board and Managing Directors. The management of operations of PCC SE now rests with a three-member Executive Board. Dr Peter Wenzel has joined the newly formed Executive Board to become its Chairman. The other two members of the Executive Board are the two former Managing Directors, Ulrike Warnecke and Dr Alfred Pelzer. Waldemar Preussner, being the only shareholder of PCC SE and until now Chairman of the Administrative Board, will be Chairman of the newly formed Supervisory Board. Dr Hans-Josef Ritzert has assumed the role of Deputy Chairman of the Supervisory Board. The Supervisory Board has been augmented by the addition of Reinhard Quint, a long-standing member of the former Administrative Board.

Projects

The joint venture between PCC SE and PETRONAS Chemicals Group Berhad (PCG) commences construction of a new oxyalkylates production plant in Malaysia. The construction site in Kertih, in the Malaysian state of Terengganu, was officially inaugurated in October 2021. The ceremony marked an important milestone for the project, the objective of which is the construction of a plant for the manufacture of specialty non-ionic surfactants and polyether polyols. At the same time, the joint venture was renamed PCG PCC Oxyalkylates Sdn. Bhd. and, along with the new company name, was also provided with a new corporate logo that symbolizes the synergies created by the unique collaboration between both chemical groups from Asia and Europe, based on the motto “East meets West”.

Holding

PCC SE starts a cooperation with Fraunhofer Institute for Solar Energy Systems ISE. The goal is the joint development of a silicon-carbon composite material to increase the performance of lithium-ion batteries. The central input for the new material is nano-silicon powder based on silicon metal, produced by PCC BakkiSilicon hf. in Iceland in an environmentally and climate-friendly manner. Silicon offers an energy density ten times higher than graphite, which is commonly used as the anode active material in lithium-ion batteries. The silicon-carbon composite material therefore significantly increases the capacity of lithium-ion batteries. This enables significantly longer ranges and shorter charging times for electric cars, for example. The two cooperation partners plan to market the innovative high-tech material as a drop-in solution for use in the manufacture of battery cells.

Projects

PCC SE and PETRONAS Chemicals Group Berhad (PCG) officially start a joint project to produce specialty chemicals in Malaysia in September. To this end, PCC SE is selling 50% of the shares in its project company PCC Oxyalkylates Malaysia Sdn. Bhd. (PCC-OM) to PCG. The objective of the 50/50 joint venture is primarily to access the markets for oxyalkylates (non-ionic surfactants and polyether polyols) in Southeast Asia and Asia-Pacific. It is planned to set up an oxyalkylates production facility in PCG’s integrated petrochemical complex in Kertih in the Malaysian state of Terengganu. The construction of the facility is targeted to commence in 2021 while production is scheduled to begin in 2023. The partners also intend to establish a joint research and development center. PCC SE had established the project company PCC-OM in 2017 with a view to expanding one of its core businesses into this growth region.

Chemicals

In view of the coronavirus pandemic, PCC is increasing its production of antibacterial soaps and disinfecting hand cleansers. The group company PCC Consumer Products Kosmet Sp. z o.o. (PCC CP Kosmet) is stepping up its production to three shifts in March, and its own, newly certified disinfectants are also going into production. In Germany, the ROKO Professional ANTI-VIRUS + disinfectant is sold from autumn in the PCC B2B online shop www.distripark.de.

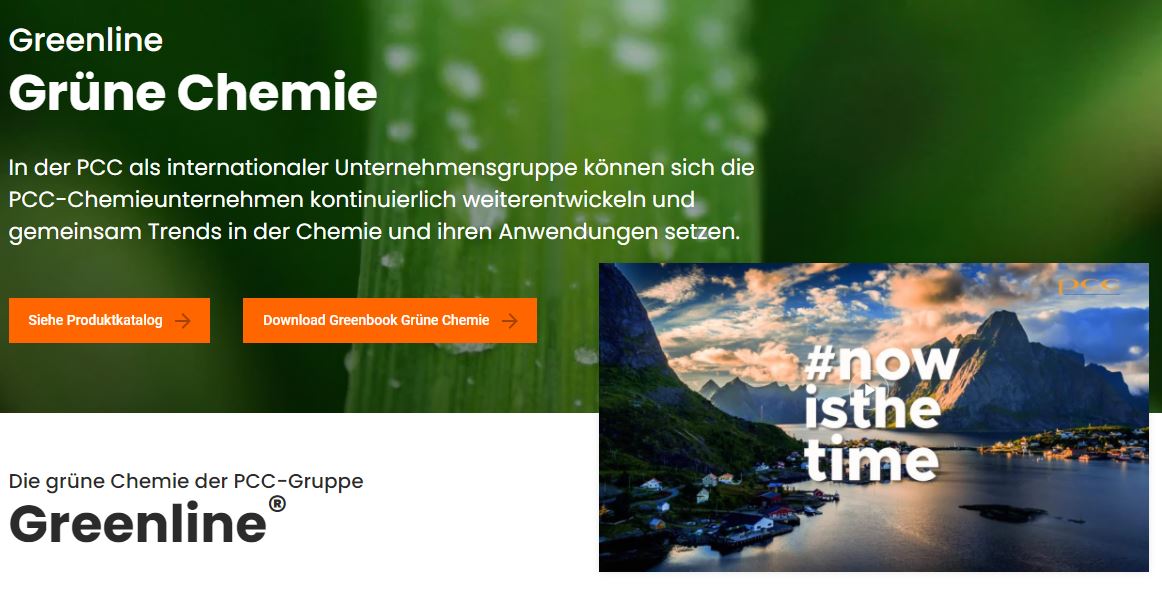

The chemical companies within the PCC Group have launched GREENLINE – a new label for a product line of sustainable chemicals. PCC’s range of “green chemicals” includes high-quality products that provide for sustainability in a variety of ways, such as chemicals that improve the effectiveness of laundry detergents at low temperatures, thus facilitating reduced energy consumption. Other chemicals are particularly suitable for the manufacture of organic and eco-products. An overview of our range can be found in the Green Chemistry section of the large product portal of our Chemicals division (https://www.products.pcc.eu/en/green-chemistry/).

Projects

The final performance test of the new production plant for high-purity, aerosol-grade dimethyl ether (DME) in Russia’s Tula region was successfully completed in May. Deliveries of this odourless and environmentally friendly propellant to the first clients were initiated.

Chemicals

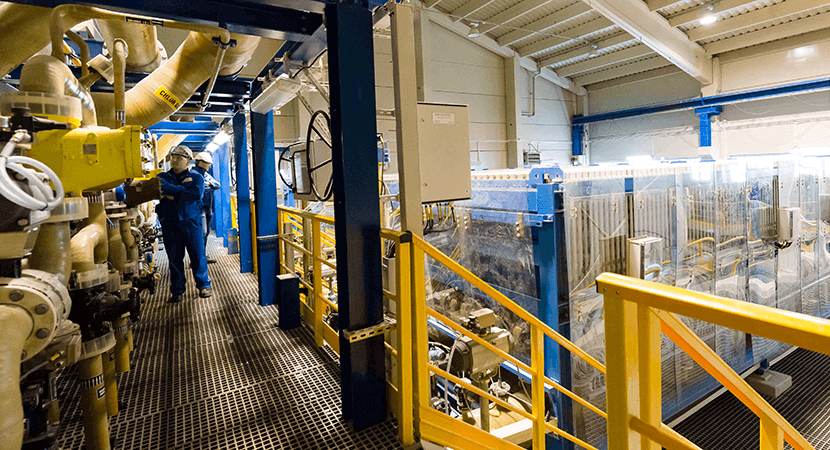

PCC Rokita SA increases the annual capacity of its chlor-alkali electrolyzis facility to 209,000 metric tons of chlorine, and 236,000 metric tons of lye. This corresponds to an increase of around 55% since 2016, which was reached initially through process optimization, followed by the addition of two additional electrolyzers in 2018 and the expansion of auxiliary facilities in the beginning of 2019. PCC Rokita SA now has a total of seven electrolyzers in its chlorine production facilities.

Logistics

Projects

In Iceland, we built one of the world’s most advanced and most environmentally compatible silicon metal production plants, which we commissioned in 2018. The plant constructor officially hands over the keys with the signing of the Final Acceptance Certificate (FAC) on October 30, 2019.

Chemicals

In the Polyols business unit, PCC Rokita SA commissiones a pilot plant with mini-reactors in which a wide range of product synthesis experiments can be carried out. In this plant, small quantities far below a ton of different polyols can be produced depending on customer requirements. In this way, PCC Rokita SA strengthens its increasing focus on higher-value specialty polyols.

Projects

The production plant for high-purity aerosol-grade dimethyl ether (DME) of our Russian joint venture DME Aerosol, Pervomaysky, as of December 2018. The commissioning process of our new 20,000 tpa plant for the production of high-purity dimethyl ether in aerosol quality was successfully started at the beginning of December. Since December 17, 2018, the plant’s production has been stable and reaching the required quality. Pictured right is the approx. 45 meter high distillation column.

The commissioning phase of our silicon metal plant in Iceland commenced on April 30, 2018 with ignition of the first electric arc furnace. After the furnace shell had been heated up, the input materials in the form of quartzite, coal and wood chip were charged in accordance with the specified ratio. The charge was heated up to around 2,000 degrees Celsius to initiate production of liquid silicon metal. The official start of production occurred with the first tapping operation performed on May 11, 2018. On August 31, 2018, the heat-up process for the second of the two arc furnaces was started.

Chemicals

In accordance with a previously agreed arrangement, PCC Rokita SA acquired a further 25% of the shares in its joint venture partner IRPC Polyol Company Ltd. from the Thai petrochemicals group IRPC Public Co. Ltd. with effect from April 30, 2018. As a result, its shareholding has increased to a total of 50%. PCC Rokita SA had initially acquired a 25% stake in the polyols and polyurethanes producer back in 2016 and is thus continuing to pursue its strategy of expansion in Asia.

Projects

Construction work on our production plant for high-purity, aerosol-grade dimethyl ether (DME) in the Tula region of Russia starts in April. The detailed engineering for the plant and the foundation work are completed by the end of June. The primary equipment and apparatus is delivered in July and the structural steel work commences in August. Commissioning of the facility is planned for December 2018.

Chemicals

To facilitate further growth in the Polyols segment, PCC Rokita SA builds a fifth production line for polyether polyols. Commissioning takes place at the end of April. This plant enables PCC Rokita SA to expand its position as the leading manufacturer of polyether polyols in Eastern Europe and also to progress its switch to higher-value specialty polyols. PCC Rokita SA also commissions a production plant for polyester polyols with an annual capacity of around 13,000 metric tons, thus further expanding the product portfolio of the Polyols segment.

Projects

The construction of an advanced silicon metal production plant in Iceland continues to progress according to schedule. The start of the year sees construction and installation work begin on the high-tension transmission lines, roads, tunnels and harbor facilities. The first major plant facility – the coal storage – is completed in the second quarter. The structural steel work of the remainder of the plant is signed off around the middle of the year, allowing work to begin on the cladding. November sees delivery of the first batch of quartzite from the PCC-owned quarry in Poland – and also a consignment of coal – to the local port of Húsavík.

Holding

In October, PCC receives further confirmation of the validity in its policy of providing support for young employees and apprentices: Justus Preiss (22) completes his apprenticeship as a wholesale and export manager at PCC SE, garnering the “best-in-class” accolade in the process. His achievement is recognized at the award ceremony held by the Lower Rhine Chamber of Commerce (IHK) in Duisburg on October 1, 2017.

Chemicals

A listed chemicals company and our largest subsidiary, PCC Rokita SA of Brzeg Dolny, Poland, is included for a second time in the RESPECT index on the Warsaw Stock Exchange in December. This sustainability index contains just two chemical concerns and only 28 of the nearly 500 companies listed on the Warsaw Stock Exchange’s main market.

Logistics

On January 4, PCC Intermodal SA – together with Hupac International SA and Kombiverkehr KG – launches a new service along the transport corridor between the Ruhr district in Germany and the heart of Poland. Four times a week, a direct train travels in both directions between the DUSS terminal in Duisburg and the PCC-owned terminal in Kutno, central Poland with load capacities running to 1,200 metric tons.

Projects

The silicon metal project in northern Iceland is proceeding according to plan after the official start of construction (September 2015). At the beginning of 2016, the detailed planning of the plant and the terracing of the site are completed, and the first foundations are built. In addition, the search for personnel for the operation of the plant, which is planned to start in 2018, was initiated and an important step was taken with the hiring of a very experienced management team. In September 2016, the 3,600 m2 coal storage hall on the top terrace of the construction site was completed. At the same time, the steel construction of the furnace house began.

Chemicals

The chemical companies PCC Rokita SA and PCC Exol SA achieve high ratings in the renowned EcoVadis sustainability rating. In February, PCC Exol SA receives the gold certificate for its corporate social responsibility (CSR) performance, making it one of the two percent of the best suppliers rated by EcoVadis in all CSR categories worldwide. At the end of 2015, PCC Rokita SA achieved silver status in the rating immediately when participating for the first time.

Logistics

At the end of April, PCC Intermodal SA establishes a container transport connection to China. The first train between the PCC terminal Kutno in Poland and the city of Chengdu in the Chinese province of Sichuan covered around 10,000 kilometers in about eleven days.

Chemicals

The year sees expansion in production capacities, in some cases substantial, and new facilities developed within the segments of the Chemicals division. For example, a new production plant for prepolymers is commissioned at PCC Prodex Sp. z o. o. in Brzeg Dolny. With an annual capacity of 7,500 metric tons, the facility counts among the three biggest of this kind in Poland. And in the Surfactants segment, PCC Exol SA builds a production plant for betaines with an annual capacity of 10,000 metric tons.

Projects

In a joint venture with our long-standing business partner JSC Shchekinoazot, we build a plant for the production of high-purity, aerosol-grade dimethyl ether (DME) in the Tula region of Russia. Its annual capacity is set at around 20,000 metric tons. At the end of June, our joint venture receives the building permit, and in July we begin preparing the construction site. Commissioning of the facility is planned for summer 2018.

Chemicals

In December 2016, PCC MCAA Sp. z o.o. successfully commissions the new MCAA plant located in Brzeg Dolny. The plant significantly extends PCC’s value chain, especially in the chlorine segment.

In December, PCC Rokita SA acquires 25 percent of the shares in the Thai polyols and polyurethanes producer IRPC Polyol Company Ltd. (IRPC Polyol), based in Bangkok. The two companies are already linked by their joint venture IRPC PCC established at the beginning of 2015 for the sale and distribution of polyols and PU systems in Southeast Asia, China and India. For PCC Rokita SA, acquisition of this stake in the joint venture partner represents the next step in its expansion in Asia.

Chemicals

In January, the chemicals concern PCC Rokita SA concludes a contract establishing a joint venture in Thailand. The purpose of the new undertaking founded in partnership with IRPC Polyol Company Ltd. is to develop the markets of South-East Asia, China and India, and thus drive the ongoing international expansion of PCC’s Chemicals division.

Holding

In May, PCC SE sells its shareholding in the Polish telecommunications company 3S S.A. to a Warsaw investment fund, marking a further success in our strategy to pursue the continuous optimization of our investment portfolio. This includes the profitable disposal of operations that lie outside our strategic core business activities.

May sees PCC SE launch its presence on the social network Facebook, thus opening up to internet users – whether customers, investors, business partners or the public at large – a further platform for direct dialogue with the company. The Facebook page constitutes a further continuation of PCC SE’s strategy of open and transparent communication with all stakeholders. Visit us on Facebook.

Projects

The financing package for the silicon metal plant planned for Iceland is finalized in June. The investment finance provided by KfW IPEX-Bank amounts to 194 million dollars, covering two-thirds of the total capital outlay. The project receives direct support from the German government through the issue of a so-called Untied Loan Guarantee (UFK) in recognition of the fact that the Icelandic plant will contribute to securing long-term commodity supplies for German industry.

Chemicals

In July, PCC Rokita SA completes the last expansion phase of its new chlor-alkali electrolysis facility based on environmentally friendly membrane technology. With the addition of a fifth electrolyzer, annual production capacity is increased to 135,000 metric tons of chlorine and 152,000 metric tons of caustic soda. Process optimization plans are in place for 2016 to further increase annual capacity to 148,000 metric tons of chlorine and 167,000 metric tons of caustic soda.

Logistics

August sees PCC Intermodal S.A. complete expansion work on its container terminal in Kutno (central Poland). Two gantry cranes have been installed and annual handling capacity has more than doubled from 100,000 TEU to 250,000 TEU (standard 20-foot containers). The PCC container handling facility in Kutno counts among Poland’s most advanced intermodal (i.e. combined transport) terminals.

Projects

The large site in Iceland on which PCC’s ultra-modern and environmentally friendly silicon metal plant is to be built is officially inaugurated on September 17. The most ambitious and costly investment project ever undertaken by PCC thus enters its construction phase. Waldemar Preussner, Chairman of the Administrative Board of PCC SE, is personally present to open the site together with high-ranking representatives of the Icelandic government, including Prime Minister Sigmundur Davíð Gunnlaugsson and Minister for Trade and Industry Ragnheiður Elín Árnadóttir.

Logistics

At the end of September, PCC Intermodal S.A. officially recommissions its expanded container terminal in Brzeg Dolny, Poland, the largest chemicals production site of the PCC Group. The annual handling capacity of the terminal has been more than doubled to 110,000 TEU (standard 20-foot containers). This project represents the third modernized and expanded terminal opened by PCC Intermodal within the last nine months.

Holding

Logistics

The end of 2015 sees PCC Intermodal SA complete work on expanding and modernizing its container terminal in Gliwice, Poland. With an operating area of 50,000 square metres, the terminal is now equipped with two new gantry cranes and has seen its handling capacity increased to more than 150,000 TEU (standard 20-foot containers). Following this terminal revamp, Gliwice now boasts the most advanced logistics centre in Poland’s Upper Silesia region.

Projects

PCC SE secures power supplies from renewable sources for its Icelandic silicon metal production facility, the commissioning of which is planned for the end of 2017/start of 2018. The project management company PCC Bakki Silicon hf., Húsavík (Iceland) was able to conclude a corresponding power purchase agreement with Iceland’s biggest utility, Landsvirkjun. The 58 megawatts required by the plant will come entirely from the output of hydroelectric, wind and geothermal power generators.

Chemicals

Further progress in the expansion of PCC’s Polyurethane Systems business is made in the first quarter of the fiscal year. PCC Prodex Sp. z o.o., Warsaw (Poland), has obtained approval in Germany for its PUR-based roof spray foam. This is applied in liquid form and then expands in seconds to create a seamless layer offering high insulation values. Newly founded PCC Prodex GmbH of Essen (Germany) is to market PUR systems in Europe’s Benelux and German-speaking countries.

April sees the stove, barbecue and hearth firelighters from PCC recognized with Poland’s “Brand of the Year” award in the Igniters category. The brand “Podpałki Czechowickie” produced by our Polish matches factory Fabryka Zapałek “Czechowice” S.A. thus takes its place as one of the most dynamic trademarks in the country.

Energy

Following some challenging construction work, PCC commissions three further small hydropower plants in the second half of the year at Galičnik, Brajčino, and Patiška in Macedonia. With these sites up and running, our Macedonian project company PCC HYDRO DOOEL Skopje has now four hydroelectric generators connected to the grid, enabling the supply of pollution-free electricity to 3,900 households.

Holding

The end of June sees PCC SE successfully place a minority package of shares in its subsidiary PCC Rokita SA on the Warsaw Stock Exchange while at the same time implementing a capital increase. Despite a difficult market environment, the private investor tranche is heavily oversubscribed with huge institutional interest. By the end of the year, the share price has increased by around 15 per cent versus the issue price of 33 złoty.

Chemicals

Following in the footsteps of PCC Rokita SA and PCC Consumer Products Sp. z o.o., in July PCC Exol SA becomes a fully fledged member of the environmental initiative Responsible Care. The surfactant producer also signs up to the UN Global Compact, an initiative of the United Nations for the promotion of sustainable development.

In August, Polish cleaning product and laundry detergent manufacturer PCC Consumer Products Kosmet Sp. z o.o. launches its new renewables-based product line Roko Eco onto the market. The line bears the EU Ecolabel.

Projects

Incisive progress with the project to establish a modern silicon metal production capability in Iceland: The Interministerial Committee of Germany’s federal government issues a preliminary confirmation of cover and the Municipal Council of Iceland’s Norðurþing district grants the construction permit.

Logistics

Installation of a new gantry crane and extensions to the railway sidings are completed in October at the PCC terminal in Frankfurt (Oder). As a result, PCC Intermodal SA is able to increase its annual handling capacity to more than 100,000 TEU (unit of measurement for 20-foot standard containers). December sees the expanded terminal officially inaugurated and handed over for service.

Energy

The European Bank for Reconstruction and Development (EBRD) rewards the successful commissioning of the first three PCC hydropower plants in Macedonia. The bank financed the projects with a loan of €6 million. The incentive bonus granted in November reduces the sum by around €670,000. In May 2015, the company is awarded an incentive payment for the successful completion of another hydroelectric generator worth approximately €160,000.

Projects

In December, PCC SE signs a contract with Iceland’s Bakkastakkur slhf. regarding its participation in the financing of a planned silicon metal production plant in Iceland. This means that the project is now fully funded. The largest part of the capital expenditure amounting to some $300 million is secured through a loan granted by KfW IPEX-Bank based in Frankfurt, while one quarter of the amount is covered by Icelandic pension funds and by Iceland’s Íslandsbanki.

Holding

The rapidly growing “PCC Consumer Products” subgroup is further expanded through the addition of further affiliates and start-ups. The subgroup now has production and sales locations in Poland and Belarus, with a trading company in Russia.

Chemicals

PCC Exol SA is nominated for the “European Small and Mid-Cap Awards” in the “Most Innovative Newcomer” category. The Polish subsidiary, of which the shares were successfully floated on the Warsaw Stock Exchange in 2012, qualifies for the competition final.

Logistics

PCC Intermodal SA starts work on expanding its combined transport terminals in Kutno and Brzeg Dolny. The Kutno terminal will have its handling capacity more than doubled from 100,000 TEU to 250,000 TEU per year with the addition of two new rail tracks and the purchase of two gantry cranes. The expansion project is expected to be completed by the first quarter of 2015.

Energy

PCC’s Macedonian project company, PCC HYDRO DOOEL Skopje, completes the small hydropower plant in Gradečka, around 90 kilometers east of the country’s capital, Skopje. In addition to the Gradečka facility, PCC is developing four further small hydropower plants in Macedonia, of which three are to be connected to the grid in 2014. With an output of around 4.1 MW, these hydroelectric power plants avoid emissions amounting to around 15,000 metric tons of CO2 per year.

The UN climate protection authority UNFCCC officially registers the first four small hydropower plants built by PCC in Macedonia as climate-protection projects compliant with the requirements of the Kyoto Protocol.

Projects

Preparations for the construction of a plant for the manufacture of high-purity monochloroacetic acid (MCAA) start on the factory site of PCC Rokita SA in Brzeg Dolny; planned capacity: 42,000 metric tons per year.

Holding

PCC SE sells 24.5 million of its shares (8.26 % of the voting rights) in the surfactant manufacturer PCC Exol SA to an international investment fund. Following this transaction, PCC SE still holds 88.12 % of the voting rights, and thus significant majority control over this affiliate. The sale proceeds per share amount to 2.3 times the book value. With this transaction, PCC SE is consistently continuing its strategy of creating corporate values and, given the opportunity, selling them in whole or in part in a timely manner.

Holding

The Polish subsidiary PCC Exol SA is listed on the Warsaw Stock Exchange. The share price has risen significantly since this IPO.

Chemicals

PCC Rokita SA opens its fourth polyols production line – capacity 30,000 tonnes annually – adding further impetus to the development of the polyols segment. The overall capacity of all four facilities reaches 100,000 tonnes per year.

Logistics

PCC Intermodal S.A. becomes operator of the “KV-Terminal” in Frankfurt (Oder), a handling terminal for combined road and rail transport. In order to enhance operational transparency of the German side of the business, a separate company – PCC Intermodal GmbH, Duisburg – is established for the activities here.

Projects

PCC SE and the Russian company JSC Shchekinoazot lay the foundation for a joint venture, OOO DME Aerosol, in a project aligned to the manufacture of high-purity dimethylether (DME) in Russia. DME is used predominantly in the cosmetics industry as a propellant in, for example, hairspray, and for the manufacture of structural polyurethane foam.

PCC SE aims to optimize its raw material supplies, starting with the establishment of PCC Organic Oils Ghana Limited, its first African project. The long-term objective is to secure the sustainable supply of raw materials for the Group-owned surfactant production facilities in Poland.

Holding

PCC sells its German electricity and gas sales operation to a Spanish investor. This transaction completes the realignment of PCC SE’s Energy division, with the original energy trading business being entirely replaced by PCC’s focus on the development and operation of its own power plants, particularly in Eastern and South-East Europe.

PCC SE establishes the holding company PCC Consumer Products S.A., Warsaw (current head office: Brzeg Dolny) in order to develop a group segment to accommodate businesses manufacturing products both for the company’s own retail brands and for the private labels of other firms.

Chemicals

PCC Exol SA, Brzeg Dolny, commissions its second ethoxylation plant in Plock, some 100 kilometres north-west of Warsaw. The facility has an annual production capacity of 30,000 metric tons of non-ionic surfactants (surface-active substances). Together with the plant already in operation on the PCC Rokita SA site, the annual capacity for the manufacture of these surfactants is this doubled to a total of 60,000 metric tons.

PCC Rokita SA sees its foam technology iPoltec® (Intelligent Polyurethane Technology) generate success in the marketplace. By the end of 2011, 1 million mattress cores have already been manufactured with this innovative technology.

Logistics

PCC Intermodal S.A. opens its Kutno container terminal. It is the first modern logistics and handling center in central Poland. Its handling capacity was 100,000 TEU (unit of measurement for 20-foot ISO containers), a figure that was more than doubled after reaching 250,000 TEU by 2015.

Projects

PCC SE commences planning work for the construction of a modern production plant for silicon metal in Iceland. Commissioning is envisaged in 2017/2018, with annual capacity set at 32,000 metric tons. The objective is to use a portion of the quartzite mined by PCC in Poland as an input material in Iceland.

Holding

Following share purchases and stock increases in 2002 and 2003, PCC SE takes over PCC Rokita SA as a wholly owned subsidiary.

PCC SE acquires 100 % of the shares in PRODEX-SYSTEM Sp. z o.o. (today: PCC Prodex Sp. z o.o., Brzeg Dolny), Warsaw, a polyurethane system house specialising in foam systems for thermal and sound insulation. Synergies are generated, in particular, with the Polyols business subunit of PCC Rokita SA.

Chemicals

PCC Rokita SA commissions its new production plant for the manufacture of specialty polyols – brand name Rokopol iPol® – which are used in the production of highly resilient and durably flexible coldfoam materials.

With the commissioning of new membrane electrolysis plant 1, PCC Rokita SA begins the process of upgrading its chlorine production facilities. The complete switchover of the chlor-alkali electrolysis process to this environmentally friendly technology is scheduled for completion in 2015.

Holding

PCC SE sells off its Polish railway activities, the “PCC Logistics” subgroup, to Deutsche Bahn AG. This divestment constitutes PCC’s biggest success to date in following its proactive investment portfolio management policy. Not included in the sale is PCC SE’s majority holding in PCC Intermodal SA, a company active in the dynamically growing Polish market for container transportation and destined to be further expanded in the coming years.

The first stock market flotation of a PCC Group company takes place with the IPO of PCC Intermodal SA, Gdynia, Poland, on the Warsaw Stock Exchange.

PCC SE purchases a majority stake in a Polish quartzite quarry. Among other things, quartzite is used in the manufacture of silicon metal employed in the chemicals industry (for the manufacture of silicone and siloxane) and also in aluminium production.

Energy

With the commissioning of the first hydropower plant in Bosnia and Herzegovina, the PCC Group commences its activities in the generation of renewable energy. With a capacity of 1.15 MW, the Mujada power plant reduces CO2 emissions in the country by 7,200 metric tons per year. Our power plant projects are planned and managed by PCC DEG Renewables GmbH, Duisburg, a joint venture between PCC SE and the KfW subsidiary DEG – Deutsche Investitions- und Entwicklungsgesellschaft mbH, Cologne.

Holding

PCC Rail S.A. acquires a majority stake in the port company in Szczecin (Poland). PCC now holds 91.4 % of the shares in this company, which is renamed PCC Port Szczecin.

In December, PCC Rokita SA sells its 90 % stake in the subsidiary Rokita-Agro S.A., a manufacturer of plant protection products and pesticides, to an Israeli investor.

Chemicals

After a construction period of 15 months, PCC Rokita SA completes its second sulfonation plant for the production of anionic surfactants. The facility’s capacity is 30,000 metric tons per year, this quadrupling the company’s surfactant production volume from 10,000 to 40,000 mt/y. A pipe system connects the new plant to the existing facility to enable optimum capacity utilization. Application of the latest technologies ensures high productivity and thus a good position on the European market. Today, the Surfactants segment belongs to PCC Exol SA, Poland’s only surfactants producer.

Energy

PCC commissions its modern cogeneration power plant known as EC-3 on the site of PCC Rokita SA. The new CHP facility (combined heat and power) significantly reduces the emissions of climate-changing gases, dust, sulphur dioxide and nitrogen compounds, including a cut in CO2 emissions of up to 40,000 metric tons per year.

Holding

PCC AG is reformed as PCC SE, making it a joint stock company under European law (Societas Europaea). The conversion to an SE is intended to express the European identity of the PCC Group. Right from the start, PCC founder and sole shareholder Waldemar Preussner saw Europe as the “home market of PCC”. Now this is to be reflected in the legal style of the Group. Becoming an SE enables PCC to efficiently coordinate crossborder business transactions and unify its Group structures.

Holding

Through the newly established company PCC Chemax, Inc., domiciled in Piedmont (South Carolina, USA), PCC takes over the division CHEMAX Performance Solutions/Polymer Additives from Rütgers Organics Corporation. The company manufactures specialty chemicals for surface treatment applications. Close cooperation with PCC Rokita SA gives rise to synergy effects in product development, raw materials supply, and product sales and distribution.

Chemicals

With the commissioning of its third polyols production line, PCC Rokita SA doubles its capacity to more than 60,000 metric tons per year. The polyether polyols manufactured by PCC Rokita are used for, among other things, the manufacture of polyurethane foams for the furniture and mattress industries. In Poland, PCC Rokita is the only producer of these polyols.

In October, PCC Rokita SA receives the “Lower Silesian Griffin” business award conferred by the Wroclaw Chamber of Commerce and the employer association Polska Miedź. This marks the start of a series of accolades for the PCC Chemicals subsidiary, which also garners the “Solid Employer 2012” title and the “Pillar of the Polish Economy 2010” award. PCC Rokita SA is one of the biggest chemicals concerns in Poland and this one of the most important employers in Lower Silesia.

Logistics

In view of very rapid business development in the railway transport sector, PCC reorganizes its Logistics division. Ten logistics companies from Poland, Germany and the Czech Republic are placed under the management of PCC Rail S.A. to form the “PCC Logistics” subgroup.

Energy

PCC begins supplying electricity between South-East Europe and Germany. The company also participates in CO2 emissions trading.

Holding

At the end of December, PCC acquires 100 % of the equity in Coaltran Sp. z o.o. (later to become PCC Rail Coaltran Sp. z o.o.). In purchasing this Warsaw railway company, PCC significantly expands its position as one of the biggest private railway operators in Poland.

Holding

PCC revamps its logo and corporate identity and introduces it across the Group for the first time. The logo is reduced to three letters – “PCC” – and widely applied to reflect PCC’s successful diversification into new business segments. The PCC logo is also now colored with the dominant shade a fresh orange, representing the energy sector on which PCC bases its growth strategy.

Energy

Holding

An increase in the shares held in PCC Rokita SA to 50.32 % brings the chemicals company into the scope of consolidation of the PCC Group for the first time.

Expansion of the Logistics division continues apace. PCC acquires a participating interest in the Polish logistics company KP Szczakowa S.A., later to become PCC Rail S.A., which at the time is already one of Poland’s biggest non-state-owned railway companies with its own fleet of around 100 locomotives and 3,600 railway wagons.

Holding

PCC AG acquires 33 % of the shares in the Polish chemicals group Rokita SA whose production facilities are located some 40 kilometres north-west of Wrocław (Breslau). These are used in the manufacture of inorganic and organic compounds for the paper, detergent, textile, cosmetics and pharmaceuticals industries. In the following years, today’s PCC Rokita SA develops into the strongest arm of the PCC Group.

Holding

PCC AG acquires around 45 % of the shares in the Polish company Sped-Kol Blachownia, which has a fleet of 700 tank wagons and also its own cleaning and repair facilities – giving birth to the Logistics division. In 2001, PCC increases its shareholding in this transport company to over 97 %.

Energy

PCC GmbH is licensed to trade on the Leipzig power exchange LPX (today EEX). In the ensuing years, it is also granted entry to the Austrian energy exchange EXAA in Graz, the French Powernext multi-trading facility in Paris and the Italian power exchange GME in Rome.

Energy

PCC GmbH is licensed as a national gas supplier for all of Germany.

Holding

Establishment of PCC AG through a carve-out from Petro Carbo Chem Rohstoffhandelsgesellschaft mbH. The company headquarters is the PCC Villa, likewise in the Duisburg district of Homberg.

PCC purchases the production plant Zakład Syntezy, known today as PCC Synteza S.A., located in the Polish town of Kędzierzyn-Koźle. This marks an important step in the development of PCC, with this site still being used today for the production of nonylphenol, a feedstock used e.g. for the manufacture of industrial cleaners and for inkjet printer cartridge charging, and dodecylphenol, an additive used in oil upgrading.

PCC AG issues the first bond on October 1st.

Energy

PCC GmbH commences electricity supply activities from countries in Central and Eastern Europe to Group companies in Germany. The supplies amount to 1.4 billion kilowatt-hours in the first trading year.

Chemicals

PCC GmbH begins processing operations in Ukraine, converting crude benzene into pure benzene, with further refinement to produce adipic acid, used in the manufacture of polyurethanes and nylon for the shoe and tyre industries. This heralds the start of PCC’s Chemicals business, currently (2013) the main revenue and earnings generator of the Group.

Holding

PCC revises its logo, giving it an identity that the Group is set to retain through the turn of the millennium and up to 2004.

Chemicals

PCC GmbH starts business on January 1. And in the first year, the commodity trading company generates sales of € 59.4 million.

Holding

Waldemar Preussner, sole shareholder and Chairman of the Supervisory Board of today’s PCC SE, founded Petro Carbo Chem Rohstoffhandelsgesellschaft mbH (PCC GmbH; now: PCC Trade & Services GmbH) in 1993 as an international trading company for petroleum-, carbon- and natural gas-based raw materials. The company headquarters remains in Duisburg-Homberg to this day. Ulrike Warnecke, current member of the Supervisory Board, was already on board. In 1995, Dr. Alfred Pelzer also joined PCC, now also a member of the Executive Board.